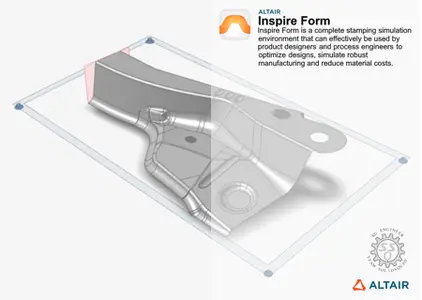

Altair Inspire Form完整的冲压仿真环境

Inspire Form 是一个完整的冲压仿真环境,产品设计师和工艺工程师可以使用该环境,有效地优化设计、对稳健的制造进行仿真、降低材料成本。

借助快速简便的可行性模块,用户可以在几秒钟内完成零部件分析,从而在产品开发早期阶段预测可成型性。自动化坯料嵌套提出了,在薄板卷材上使用压成扁坯坯料的有效布局,从而尽可能提高材料使用率。

试模模块包含一个具有出色可扩展性的增量求解器,可帮助用户在直观的用户界面中对多工步成型、修剪和回弹进行迭代及仿真,从而降低复杂性并使高品质零部件的生产更具经济效益。

Altair has released Inspire Form 2025.0 is a unique software that enables users to optimally design sheet metal components considering manufacturing feasibility and material cost.

Resolved Issues

The following issues have been resolved for the 2025 release:

General:

– Section view is now shown along the section cut plane for surface/sheet parts [INSFORM-3089].

– Box fit measure has been improved for accuracy and compactness [INSFORM-2878].

Feasibility

– Blank fit has been improved for accuracy [INSFORM-2512].

Tryout:

– Inspire Form solver now runs single and multioperation forming simulation in all supported Linux distributions [INSFORM-3163].

– Yoshida (Original) and Yoshida (Modified) hardening are now supported for materials when a Barlat 3 parameter is selected in the Materials dialog [INSFORM-3075]

– Reports now include thickness and %thinning results for blanks modeled with solid elements [INSFORM-3119].

– Inspire Form solver now runs with adaptive mesh and improved stability [INSFORM-3213].

– Drawbead parameters are now saved with .iform files [INSFORM-2512].

– Solid-blank meshing has been improved to create uniform layers of hexa and penta elements [INSFORM-3073].

– Blank shape prediction robustness has been improved to handle complex outlines and holes [INSFORM-3109].

Altair Inspire Form is a complete stamping simulation environment that can effectively be used by product designers and process engineers to optimize designs, simulate robust manufacturing and reduce material costs. With the fast and easy feasibility module, users can analyze parts in seconds to predict formability early in the product development cycle. The automated blank nesting proposes an efficient layout of the flattened blank on the sheet coil to maximize material utilization. The tryout module includes a highly scalable incremental solver, helping users to iterate and simulate multi-stage forming, trimming and springback in a modern and intuitive user interface, reducing complexity and making the production of high quality parts more economical. Altair Inspire Form also offers an innovative user experience to seamlessly transition between design and analysis through a highly intuitive user interface designed for beginners and experts alike. It enables part and process designers to evaluate manufacturability early in the development cycle to avoid costly trials downstream. Altair Inspire Form automatically generates a report for fitted and nested blanks to help maximize material utilization

This quick video tutorial shows how to perform a manual setup in the tryout (incremental analysis) workflow.

Altair Engineering, a global technology company headquartered in Troy, Michigan, USA, with operations across the Americas, Europe, and Asia-Pacific, offers Altair Hyperworks, a cutting-edge Computational Fluid Dynamics (CFD) software solution. Designed primarily for mid-sized to large enterprises across various industries, including automotive, aerospace, energy, and manufacturing, Hyperworks empowers engineers and researchers to simulate and analyze fluid flows, heat transfer, and related phenomena with unparalleled accuracy and efficiency.

Owner: Altair Engineering

Product Name: Inspire Form

Version: 2025.0

Supported Architectures: x64

Website Home Page : http://www.altair.com

Languages Supported: english

System Requirements: Windows *

Size: 5.4 Gb

解压密码:caxfwz

下单请慎重!本站目前只提供软件安装资源,不提供软件安装服务,对软件安装不熟悉者,只能自己通过其他途径解决。

请先 !