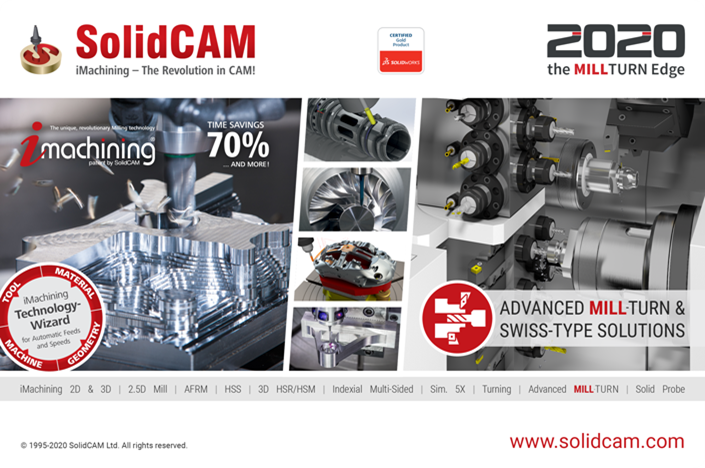

SolidCAM软件支持所有类型的CNC应用,是无缝集成于SOLIDWORKS的CAM软件的领导者。SolidCAM + SOLIDWORKS提供最佳的无缝集成CAD / CAM解决方案:

- 直接在SOLIDWORKS中运行,无缝集成于同一窗口

- SolidCAM 与SOLIDWORKS的模型完全相关联,模型发生改变,相应的刀路也会自动更新

- 与SOLIDWORKS是有超过10年合作历史的CAM黄金合作伙伴

SolidCAM StandalonCADe – A SOLAR system with a built-in CAD system (does not require a pre-installed SolidWorks or other CAD system)

This system is a comprehensive solution for metal-processing automation. Using a wide range of SolidCAM strategies, turning, milling, turning-fraser and electroerosionic processing, the technologist can prepare the necessary set of control programs for mechano processing of the product in a short time.

SolidCAM Features

2.5-coordinate milling

SolidCAM provides high efficiency and precision in 2.5-coordinate milling parts. Various strategies for processing elements such as contour, sampling (with islands) and grooves are supported, as well as different types of hole processing: drilling, zenkering, carving, etc.

3-coordinate milling

SolidCAM provides a wide range of tools that can be used effectively to process products with complex geometry (stamps, molds) and prismatic parts. A three-dimensional surface or solid state model is used as a geometry for 3-coordinate processing. The system supports different types of draft and clean processing strategies, such as waste processing with a predetermined or automatically defined waste angle, ecvidistante processing, projection, waterlinia processing, etc.

In addition to the 2.5- and 3-coordinate processing capabilities already listed, SolidCAM offers tools to identify and refine sites not processed at previous crossings. It is possible to create a database of typical processes. Once created, such a parametric process can be reused in the future, which significantly reduces the time of production preparation, increases the reliability of developed programs, unifies the style of technological developments, guarantees the use of only optimal processing technologies and ensures the independence of production from the human factor. The absence of stabbings is guaranteed by the availability of means of control and visualization of mechano processing.

Multi-axis processing

SolidCAM offers a variety of tools to create multi-axis management programs at 4- and 5-coordinate processing centers. The model is installed in a user-defined processing plane, after which the system automatically calculates all the necessary offset and rotation parameters for the part zero. As a result, the preparatory and final transition time is significantly reduced and processing accuracy is improved.

Turning and turning-fraser treatment

SolidCAM has a wide range of features to automate the creation of control programs for turning and turning-fraser processing. SolidCAM supports different types of tool, which allows efficient longitudinal sharpening, cutting of ends, groove processing, etc. Maintaining a rotating tool allows milling and drilling to be performed at processing centers.

Electroerosion treatment

SolidCAM’s proposed set of wire electroerosionic processing strategies allows for the processing of external and internal contours with a constant and variable angle of inclination. There is a possibility of 4-axis treatment. A special algorithm prevents the processed material from falling. SolidCAM provides the user with a means of controlling the physical parameters of processing throughout the trajectory of the wire.

Attention!

If you have SolidWorks installed, don’t install SolidCAMCAD!

In this case, you need a plug-in for SolidWorks- SolidCAM

百度网盘下载:

本站解压密码:caxfwz

请先 !